Table of Contents

ToggleA Closer Look at 3173 Oil Seal and 33712 Double Lip Oil Seal: Dimensions, Applications, Costs, and Market Insights

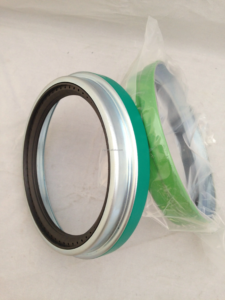

Oil seals, also known as shaft seals or radial lip seals, are essential components in mechanical systems. They prevent fluid leakage and protect machinery from contaminants, ensuring optimal performance and extended equipment lifespan. Among the many models available, the 3173 oil seal and 33712 double lip oil seal stand out for their versatility and reliability in a range of industrial and automotive applications. This article explores these two models, detailing their dimensions, applications, costs, lifespans, and market trends.

1. 3173 Oil Seal: Dimensions, Applications, and Features

Dimensions and Specifications

The 3173 oil seal is a widely used model, designed to fit standard industrial and automotive systems. Its typical specifications include:

- Inner Diameter (ID): ~37mm

- Outer Diameter (OD): ~50mm

- Thickness: Ranges between 6mm and 10mm, depending on the variant.

The dimensions of the 3173 oil seal make it suitable for sealing shafts in moderate to high-speed applications, ensuring optimal performance in systems requiring a compact seal.

Applications

The 3173 oil seal is a versatile component used in:

- Automotive Systems: Found in engine crankshafts, differentials, and transmissions, it prevents oil leakage and protects against contaminants.

- Industrial Machinery: Used in pumps, compressors, and gearboxes, where fluid sealing is critical.

- Hydraulic Equipment: Ensures hydraulic fluid containment in systems like cylinders and valves.

Materials

The 3173 oil seal is commonly manufactured from durable materials such as:

- Nitrile Rubber (NBR): Excellent resistance to oils and moderate temperatures.

- Viton (FKM): Ideal for high-temperature and chemically aggressive environments.

Cost and Lifespan

The price of a 3173 oil seal ranges from $5 to $15, depending on material and supplier. With proper maintenance, its lifespan averages 1-3 years, depending on operational conditions and rotational speed.

2. 33712 Double Lip Oil Seal: Dimensions, Features, and Applications

Dimensions and Specifications

The 33712 double lip oil seal features a robust design with two sealing lips for enhanced performance. Its typical dimensions are:

- Inner Diameter (ID): ~37mm

- Outer Diameter (OD): ~52mm

- Thickness: ~8mm

The double lip design offers two layers of protection: one lip seals fluid, while the other prevents contaminants from entering, making it ideal for demanding applications.

Applications

The 33712 double lip oil seal is particularly effective in:

- High-Pressure Systems: Used in hydraulic pumps and cylinders to maintain fluid pressure and block debris.

- Automotive Components: Found in wheel bearings, axles, and differentials, especially in high-speed and high-temperature environments.

- Industrial Machinery: Common in equipment like turbines, conveyors, and vacuum systems, where dual protection is required.

Materials

The 33712 double lip oil seal is often crafted from:

- Viton (FKM): For extreme temperatures and chemical exposure.

- Silicone Rubber: Provides flexibility and low friction in high-heat environments.

Cost and Lifespan

With enhanced functionality, the 33712 double lip oil seal typically costs $10 to $30. Its lifespan is slightly longer than single-lip seals, averaging 2-5 years in standard conditions.

3. Key Differences Between 3173 Oil Seal and 33712 Double Lip Oil Seal

| Feature | 3173 Oil Seal | 33712 Double Lip Oil Seal |

| Design | Single lip | Double lip |

| Applications | General-purpose | High-pressure, demanding |

| Cost | $5–$15 | $10–$30 |

| Lifespan | 1–3 years | 2–5 years |

| Materials | NBR, Viton | Viton, Silicone |

The 3173 oil seal is better suited for standard sealing tasks, while the 33712 double lip oil seal excels in challenging environments requiring additional durability and contamination resistance.

4. Market Trends and Insights

Demand and Growth

The global oil seal market is expanding due to increased industrialization and automotive production. The 3173 oil seal and 33712 double lip oil seal are high-demand models, with applications spanning multiple sectors.

Customization Needs

Modern industries require seals tailored to specific needs, such as higher durability, chemical resistance, and size adjustments. This trend has driven innovation, especially for models like the 33712 double lip oil seal, which offers superior sealing solutions.

Material Advancements

Materials like Viton, EPDM, and advanced composites are gaining traction, offering improved performance and lifespan. These materials enhance oil seal resistance to heat, chemicals, and wear, catering to industries with demanding conditions.

Costs and Competition

Basic oil seals like the 3173 oil seal remain affordable for general use, while specialized options such as the 33712 double lip oil seal are priced higher due to their complexity. Suppliers like China Feiyun Seal Factory offer competitive prices and customizable solutions, making them a preferred choice for bulk orders.

5. Future Outlook

The oil seal market is projected to grow significantly, driven by advancements in automotive technology, industrial equipment, and hydraulic systems. High-performance models like the 33712 double lip oil seal are expected to see increased adoption due to their versatility and reliability. Additionally, the push for environmentally friendly materials and processes will shape future oil seal innovations.

Conclusion

Both the 3173 oil seal and 33712 double lip oil seal serve as vital components in modern machinery. While the 3173 oil seal offers cost-effective solutions for general-purpose applications, the 33712 double lip oil seal provides enhanced protection for demanding environments. Their durability, affordability, and adaptability ensure their continued relevance across industries. For businesses seeking high-quality seals, suppliers like China Feiyun Seal Factory offer a wide range of options, including customization to meet specific requirements.

Leave A Comment