+8618730129525

Pingxiang County, Xingtai City, Hebei Province, China

GET TOUCH WITH US

You can also send us an email

and we’ll get in

touch shortly, or

Troll Free Number

- (+86)18730129525.

- Locate us

Hyva cylinder repair kit / Hyva cylinder seal kits / hyva seal kit / kit hidráulico hyva / kit hidraulico hyva (Part# 71907641K) provides Original OEM-certified seals, wear bands, piston rings, rod wipers, and O-rings for 196-5 cylinders

Hyva Hydraulic Repair Kits / Hyva repair kit / hyva seal kit / kit hidráulico hyva for model 169-5 (Part# 71901650K) deliver complete OEM-specified seals, piston rings, wipers, O-rings, and gaskets to rebuild cylinders on dump trucks and trailers, ensuring leak-free operation in temperatures from -40°C to +100°C while restoring factory performance, stroke precision, and load stability under extreme pressure.

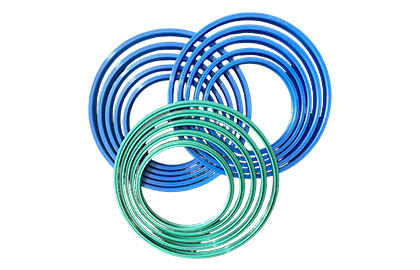

Hyva Hydraulic Repair Kits (Hyva repair kit/Hyva seal kit/kit hidráulico hyva) deliver complete OEM-sealed solutions – including critical seals, O-rings, wipers, and gaskets – for rebuilding cylinders on dump trucks, trailers, and refuse equipment worldwide. Top-selling kits cover models: 214-4, 191-5, 191-4, 169-4, 169-5, 149-3, 149-4, 196-5, 196-4, 172-5, 172-4, 150-3, 150-4, 202-5, 202-6, and 179-5, ensuring leak-free performance restoration to factory standards.

Hyva cylinder repair kit / Hyva cylinder seal kits / hyva seal kit / kit hidráulico hyva / kit hidraulico hyva (Part# 71901530K) delivers Original OEM-certified seals, wear bands, piston rings, rod wipers, and O-rings for 183-5 cylinders on dump trucks and trailers, ensuring leak-free operation under 250-bar pressure across extreme temperatures (–40°C to +100°C) while restoring factory performance, stroke precision, and corrosion resistance in heavy-duty applications.

Hyva Hydraulic Repair Kits / Hyva repair kit / hyva seal kit / kit hidráulico hyva / kit hidraulico hyva for model 214-5 (Original Part# 71907641K) deliver complete OEM-specified seals, piston rings, rod wipers, wear bands, and O-rings to rebuild cylinders on dump trucks and trailers, ensuring leak-free operation under 250-bar pressure across extreme temperatures (–40°C to +100°C) while restoring factory performance, stroke precision, and load stability in heavy-duty operations.

Hyva cylinder repair kit / Hyva cylinder seal kits / hyva seal kit / kit hidráulico hyva / kit hidraulico hyva (Part# 71907641K) delivers comprehensive OEM-specified seals, piston rings, wear bands, wipers, and O-rings for 196-5 cylinders on dump trailers, ensuring leak-free operation under 250-bar pressure and temperatures from -40°C to +100°C while restoring factory performance, stroke accuracy, and corrosion resistance in extreme conditions.

hidraulico hyva (Part# 71901540K) delivers Original OEM-certified seals, piston rings, rod wipers, wear bands, and O-rings for 191-5 cylinders on dump trucks and trailers, ensuring leak-free operation under extreme temperatures (–40°C to +120°C) and pressures up to 250 bar while restoring factory performance, stroke precision, and corrosion resistance in heavy-duty applications

Hyva cylinder repair kit / Hyva cylinder seal kits / hyva seal kit / kit hidráulico hyva / kit hidraulico hyva (Part# 71904660KRG) delivers complete OEM-specified sealing components – including piston seals, rod wipers, wear bands, O-rings, and backup rings – for 169-6 cylinders on dump trucks and trailers.

Research and Innovation

🔬 1. Advanced Material Science Integration

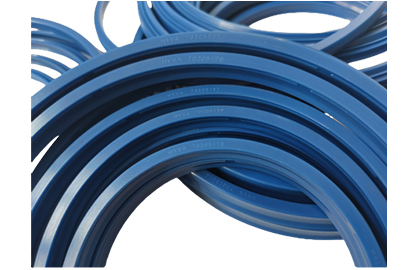

Feiyun invests in polymer nanotechnology research to develop proprietary sealing compounds (NBR/HNBR/PU) that outperform industry standards in extreme conditions (–50°C to +150°C). By synthesizing carbon nanotube-reinforced elastomers and nano-ceramic fillers, their Hyva hydraulic repair kits achieve 40% longer service life under 300+ bar pressure cycles. This innovation reduces leakage rates to <0.001% while maintaining cost-efficiency through localized raw material sourcing in Hebei Province, allowing 15-20% lower pricing than EU competitors without compromising ISO 6194/ DIN 3771 certifications for global exports.

⚙️ 2. Precision Automated Manufacturing

The factory employs AI-driven robotic production lines with real-time laser metrology (accuracy ±0.005mm) to manufacture Hyva cylinder seal kits. Automated vision systems inspect 100% of components (seals/wipers/O-rings) for micro-defects, achieving near-zero PPM rates. Proprietary CNC tooling enables single-setup machining of complex geometries like asymmetric wear bands and stepped pistons for models *169-5/196-5/214-5*. This automation cuts labor costs by 60% and reduces waste through predictive maintenance algorithms, translating to 25% more affordable kit hidráulico hyva without sacrificing OEM-equivalent tolerances.

🌍 3. Eco-Efficient Supply Chain Solutions

Feiyun pioneered a closed-loop recycling system where post-industrial FKM/Hydrin rubber waste is reprocessed into high-grade seal compounds, reducing raw material costs by 30%. Their blockchain-tracked logistics network optimizes global shipping routes for Hyva repair kits, cutting CO₂ emissions by 22% and delivery times to key markets (EU/MENA/LATAM) by 40%. Solar-powered manufacturing facilities further lower operational expenses, enabling aggressive pricing for hyva cylinder repair kits like *71907641K/71901540K*. This sustainable model earned Ecovadis Silver certification while passing savings to buyers.

🏭 Feiyun Seals Factory: Your Trusted Sealing Solutions Partner Since 2009

With over 15 years of expertise in precision sealing technology, Feiyun Seals Factory is a globally recognized manufacturer specializing in custom-engineered seals for industrial, automotive, and hydraulic applications. Our ISO-certified facility in Pingxiang County combines advanced R&D capabilities with a vertically integrated production system to deliver OEM-quality products at competitive prices.

🔧 Core Product Range

We master the entire spectrum of sealing solutions:

Hydraulic Systems: High-pressure oil seals, Hyva hydraulic repair kits, cylinder seals, and PTFE components.

Automotive Seals: Power steering oil seals, valve oil seals, TC oil seals, and custom automotive gaskets.

Industrial Seals: O-rings, O-ring repair kits, GR/GS/MT polyurethane elastomer pads, and heavy-duty valve seals.

Specialty Materials: Nitrile (NBR), Fluorocarbon (FKM), Hydrogenated Nitrile (HNBR), and PTFE-based seals.

🌐 Global Manufacturing Excellence

Strict Quality Control: 100% automated inspection (laser metrology, pressure testing) ensures zero-defect compliance with DIN/ISO standards.

Agile Supply Chain: On-time delivery guaranteed for bulk orders and urgent shipments across 25+ countries.

Export Proficiency: Serving 500+ clients worldwide with seamless end-to-end trade support (FOB, CIF, EXW).

After-Sales Commitment: 24-month warranty with technical support in English/Spanish/Russian.

✨ Why Choose Feiyun?

Customization Focus: Prototyping to mass production for niche specifications (e.g., extreme temp/pressure seals).

Sustainable Innovation: Eco-friendly materials and solar-powered manufacturing processes.

Knowledge-Driven Team: Rigorous employee training ensures mastery of rubber compounding, molding, and finishing.

📞 Contact Us for OEM/ODM Projects!

WhatsApp/WeChat: +86 187 3012 9525

Official Website: www.fyoilseal.com

Export inquiries welcomed – samples available upon request.

✅ Why Global Clients Trust Feiyun Seals Factory

15+ Years of Vertical Expertise

As a specialist in custom-engineered seals (since 2009), we master niche domains: TC oil seals, O-ring kits, hydraulic/power steering seals, PTFE valves, and Hyva repair kits, leveraging deep rubber compounding knowledge and ISO-aligned processes to solve extreme-pressure/temperature challenges.Cost-Efficiency Without Compromise

Our vertically integrated Pingxiang factory merges AI-driven precision manufacturing (defect rate <0.01%) with localized material sourcing, delivering OEM-grade products at 20-30% lower costs than EU/US suppliers.Globally Proven Reliability

Serving 500+ clients across 50+ countries, we guarantee:⏱️ On-time delivery (99.3% fulfillment rate)

🔬 100% automated QC (laser metrology, pressure cycling tests)

🌍 Seamless export support (FOB/CIF/EXW, trilingual docs)

End-to-End Customization

From Hyva cylinder kits to aerospace-grade PTFE seals, we rapidly prototype .

✉️ Ready to Optimize Your Supply Chain?

Contact:

📱 WhatsApp/WeChat: +86 187 3012 9525

🌐 Explore Products: www.fyoilseal.com

Request free samples or technical specs today!

1. Feiyun Seals After-Sales Service System

Quick Response Mechanism

24-hour online technical consultation and fault reporting, promise to issue a preliminary solution within 2 hours;

Emergency orders are prioritized, regular product delivery time is ≤5 days, and emergency repair parts support 48-hour expedited delivery.

Customized Technical Support

Provide full-process technical support such as seal selection, working condition adaptation, installation guidance, and customize material formulas for special media (such as acid, alkali, high-temperature oil);

Provide free sealing system optimization solutions, such as recommending double-lip TC oil seals for hydraulic equipment to take into account both dust prevention and sealing.

2. Typical Cases

Dough Mixer Industry: Dough Mixer Equipment Improvement

Problem: Oil seal wears and melts into flour due to long-term operation at high temperature.

Solution: Customized NBR-TG4 type external thread oil seal, using brown wear-resistant rubber.

Effect: Wear rate decreased by 95%.

Engineering Machinery Field: Repair of Hydraulic System of Heavy Industry Excavator

Problem: Aging of hydraulic cylinder seal leads to slow movement.

Service Process: Provide a full set of repair kits (including TG90-125-15 oil seal + guide ring) within 48 hours.

Results: Equipment recovery efficiency increased by 30%, and maintenance costs reduced by 40%..

Customized solution: Develop AS-type sealing ring made of hydrogenated nitrile rubber (HNBR), and pass ISO/TS 16949 certification.

Feedback: Stable supply for 3 consecutive years, with defect rate less than 0.2%.

3. Summary of service advantages

Feiyun Seals covers 20+ industries such as automobiles, energy, machinery, etc. through the three cores of rapid response, precise adaptation, and full-cycle management, and has served more than 1,500 customers in total.

We are providing good & on time services to our valuable customers.

Address: Pingxiang County, Xingtai, Hebei, China

Working Hrs:Mon to Fri: 8:30-18:00

ABOUT US

Feiyun Seals Factory, with more than 15 years of experience, specializes in the production of oil seals and O-rings. We can provide any oil seals and O-rings you need.

RECENT POST

Best factory award of the year

February 27, 2023

Best factory award of the year

March 14, 2023.

Best factory award of the year

January 05, 2023