Table of Contents

ToggleLearn all about O-rings

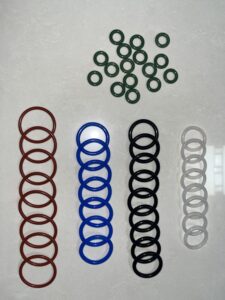

In modern engineering and manufacturing, sealing components play a vital role. As a common sealing solution, O-rings are widely used in various industrial fields due to their simple and effective design. This article will take a closer look at the different types of O-rings, including Viton O-rings, silicone O-rings, NBR O-rings, EPDM O-rings, and other related seals to help you understand how to choose the sealing solution that suits your needs.

Basic knowledge of O-rings

The O-ring is an initial seal, usually made of elastic material. Its main function is to prevent leakage of liquid or gas and ensure the safety and functionality of the system. O-rings are designed to be simple yet effective and are suitable for use in a variety of applications, including automotive, aerospace, manufacturing and home appliances.

Common O-ring materials

Viton O-ring

The Viton O-ring is a seal made of fluoroelastomer (FKM). It has excellent resistance to heat, chemicals and oils, so it performs well in high temperatures and harsh environments. Viton O-rings are particularly suitable for use in petroleum, chemical and hydraulic systems. They maintain their elasticity and sealing properties under extreme temperatures and chemical media.

Silicone O-ring

Silicone O-rings are made of silicone rubber and have excellent high temperature resistance and elasticity. Silicone O-rings have a wide operating temperature range and can maintain stable performance from -60°C to +200°C. In addition, they are highly resistant to a wide range of chemicals and are suitable for use in areas requiring high cleanliness, such as medical equipment, food processing and electronics.

NBR O-ring

NBR O-rings are known for their good oil resistance and wear resistance. They are suitable for sealing a variety of petroleum-based and water-based liquids. NBR O-rings are widely used in the automotive industry and hydraulic systems because of their ability to effectively resist attack by fuel, lubricants, and other chemicals.

EPDM O-ring

EPDM O-rings have excellent ozone resistance, weather resistance and heat resistance. They perform well in low and high temperature conditions while also being highly resistant to water and steam. EPDM O-rings are commonly used in automotive cooling systems and water treatment equipment, especially where weather resistance is required.

Other types of O-rings

Square O-ring

Square O-rings have a square cross-section, and they can provide a better seal in some applications than traditional round O-rings. Square O-rings are usually used in situations where high pressure is tolerated or special sealing properties are required.

Flat O-ring

Flat O-rings are seals with a flat cross-section and are suitable for applications that require a larger contact area. They distribute pressure evenly during the sealing process and are suitable for use in a variety of industrial equipment.

The selection and use of O-rings

When selecting an O-ring, in addition to considering its material, you also need to pay attention to the following factors:

1.Dimensions: Make sure the inner and outer diameters of the O-ring are appropriate for your application needs. An O-ring that is too large or too small will affect the sealing effect.

2.Hardness: The hardness of O-rings is usually expressed in Shore A. Depending on the different needs of the application, choosing an O-ring of appropriate hardness can improve sealing performance.

3.Temperature range: O-rings made of different materials behave differently at different temperatures. Be sure to choose an O-ring that can maintain elasticity and sealing performance in your application environment. Usually the use temperature of nitrile is 150℃, and that of fluorine rubber is 250℃.

4.Chemical Compatibility: If your application involves chemicals or grease, choosing a chemical-resistant O-ring material is key to avoid seal failure due to chemical reactions.

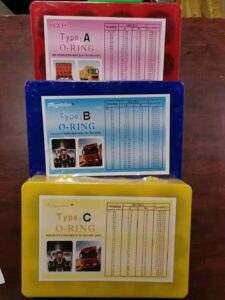

O-ring kits and accessories

To meet different needs, a variety of O-ring kits and accessories are available on the market. These kits typically include O-rings in a variety of sizes and materials, allowing users to select the appropriate seal for specific needs. In addition, some packaging forms, such as O-ring boxes or O-ring sealant pads, also provide users with more choices and convenience.

Summarize

O-rings play an important role in industrial and household applications as an efficient sealing solution. Understanding the different types of O-rings and their material properties can help you make more informed decisions in selection and application. Whether it is Viton O-ring, silicone O-ring, NBR O-ring, or EPDM O-ring, each material has its unique advantages and scope of application. By correctly selecting the right O-ring, you can ensure the sealing performance of your equipment and systems, extend their service life, and improve overall efficiency.

Leave A Comment