Table of Contents

ToggleComprehensive Guide to O-Rings: Types, Materials, and Sizing

Introduction to O-Rings

An O-ring is a mechanical gasket shaped like a doughnut or ring, typically used to seal two components in machinery and prevent fluid or gas leakage. O-rings are crucial in various industries, including automotive, aerospace, pharmaceuticals, and hydraulics, due to their simple yet effective design.

Types of O-Rings

- Viton O-Ring: Made from fluorocarbon elastomers, Viton O-rings offer excellent chemical resistance and can withstand high temperatures. They are commonly used in automotive and aerospace applications.

- Silicone O-Ring: These are flexible, resistant to extreme temperatures, and often used in food-grade applications due to their non-toxic nature.

- NBR O-Ring (Nitrile): Known for its oil and fuel resistance, nitrile rubber O-rings are commonly used in fuel systems and hydraulic applications.

- EPDM O-Ring: Ideal for applications involving water, steam, or chemicals, EPDM O-rings are commonly used in plumbing and HVAC systems.

- PTFE O-Ring: Made from Teflon, PTFE O-rings have excellent chemical and temperature resistance, making them suitable for harsh chemical environments.

- FFKM O-Ring: Perfluoroelastomer (FFKM) O-rings provide superior chemical and heat resistance, often used in demanding environments like semiconductor manufacturing.

O-Ring Materials

The choice of material depends on the application, operating environment, and chemicals involved. Key materials include:

- Viton (Fluorocarbon): Great for high temperatures and harsh chemicals.

- Nitrile (NBR): Best for oil and petroleum-based products.

- Silicone: Suitable for extreme temperatures, both high and low.

- EPDM: Good for water, steam, and UV exposure.

- PTFE (Teflon): High chemical resistance, but less flexible than rubber.

- FKM (Fluoroelastomer): Excellent for resistance to heat and aggressive chemicals.

Standard O-Ring Sizes and Dimensions

O-rings come in various sizes, and their dimensions are typically defined by their inner diameter (ID), outer diameter (OD), and cross-section thickness (CS). Standard O-ring size charts provide dimensions in millimeters (mm) and are essential for selecting the correct O-ring.

O-Ring Size Chart in mm:

- Example: 18×3 O-Ring (ID = 18 mm, CS = 3 mm).

For precise applications, manufacturers often provide size charts or online calculators like the Parker O-Ring Calculator to help choose the right dimensions.

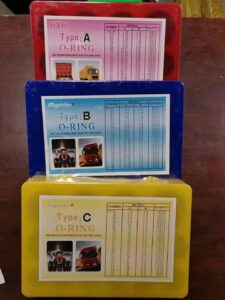

O-Ring Kits and Accessories

- O-Ring Kit: These kits typically contain a range of O-ring sizes and materials, ideal for maintenance and repair jobs.

- O-Ring Cord: Allows for custom-sized O-rings to be created on-site.

- O-Ring Gasket: Used as a sealing component between two surfaces.

Applications and Manufacturers

Numerous manufacturers specialize in O-ring production, offering custom and standard O-ring solutions. Some well-known names include Parker O-Rings and Max Spare O-Rings, both of which supply O-rings in various materials and sizes.

How to Select the Right O-Ring

Factors to consider when selecting an O-ring include:

- Material compatibility: Ensure the O-ring material is compatible with the fluid or gas it will be exposed to.

- Operating temperature: Some O-ring materials, like Viton and FFKM, can withstand higher temperatures than others.

- Pressure: Different applications demand O-rings that can handle varying pressure levels.

For accurate sizing, tools like an O-Ring Size Chart or O-Ring Calculator are invaluable.

Conclusion

O-rings are versatile, essential components in sealing applications across industries. By understanding the different types of O-rings, materials, and sizes available, you can ensure optimal performance and longevity in any application. Whether you’re using standard O-rings, customized solutions, or specialty O-ring materials like Viton or PTFE, proper selection is key to maintaining efficient operations and preventing leaks.

Leave A Comment