Understanding M92074 Oil Seal, Oil Seal 12456, TB110 Oil Seals, PPS Oil Seal, and CFW BAFSL Oil Seal: Key Insights for Optimal Sealing Performance

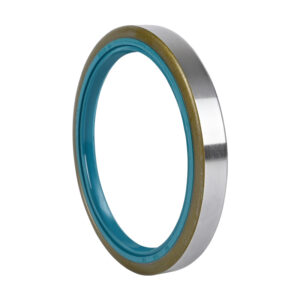

Oil seals are critical components in a wide range of machinery, designed to prevent the leakage of lubricants and protect against contaminants. Whether in automotive, industrial, or manufacturing applications, selecting the right oil seal is vital for maintaining equipment efficiency and longevity. In this article, we will explore five different oil seals: M92074 oil seal, oil seal 12456, TB110 oil seals, PPS oil seal, and CFW BAFSL oil seal. Each type has unique features that make it suitable for specific needs. Understanding these seals’ design, material properties, and applications will help you make informed decisions to optimize performance and avoid downtime.

Table of Contents

Toggle1. M92074 Oil Seal: Robust Performance for Diverse Applications

The M92074 oil seal is a well-known seal used in a variety of industrial and automotive applications. Known for its durability and adaptability, this seal is designed to handle medium to heavy-duty operations.

Key Features:

- Material Composition: Typically made from nitrile rubber (NBR), this seal offers excellent resistance to oil, water, and heat. In some cases, it may be available in other materials like fluoroelastomers (FKM) for high-temperature applications.

- Design: The M92074 oil seal is designed to provide a tight and effective seal between moving parts. The inner lip of the seal ensures that lubricants are kept contained, while the outer lip prevents external contaminants from entering.

- Durability: This oil seal is built to withstand high-pressure environments, providing a long service life in critical machinery applications.

Applications:

- Automotive: Frequently used in car engines, transmissions, and differentials to prevent oil leaks.

- Heavy Machinery: Common in industrial machinery and equipment, such as pumps and gearboxes.

- Hydraulic Systems: Effective in hydraulic cylinders, ensuring that fluid stays sealed and contaminants do not interfere with the operation.

2. Oil Seal 12456: Precision and Versatility for Various Systems

The oil seal 12456 is a popular sealing solution that provides excellent performance in both industrial and commercial applications. Its precision and versatility make it ideal for applications that require both sealing efficiency and durability.

Key Features:

- Material Variety: Oil seal 12456 can be made from various materials, such as nitrile rubber (NBR), silicone, or PTFE, depending on the specific needs of the application.

- Size and Fit: This oil seal is available in different sizes, ensuring a perfect fit for various shafts and housings. Its design features a reinforced structure to improve resistance to wear and tear.

- High Resistance: Known for its high resistance to oils, water, and even some chemicals, the oil seal 12456 is designed to perform reliably in harsh environments.

Applications:

- Automotive: Commonly used in transmissions, axles, and other vehicle components that require reliable sealing.

- Agricultural Equipment: Utilized in tractors and harvesters to prevent oil leakage from moving parts.

- Industrial Machines: Found in machinery such as conveyor systems, industrial pumps, and compressors to ensure proper fluid containment.

3. TB110 Oil Seals: High-Performance Sealing for Tough Applications

The TB110 oil seal is recognized for its high performance in challenging applications where durability is essential. Its robust design and material properties make it a go-to choice for industries that require seals with high wear resistance and reliability.

Key Features:

- Double Lip Design: The TB110 oil seal is often equipped with a double-lip design, providing enhanced sealing performance by offering an additional barrier against contaminants.

- High-Speed Performance: This seal is designed to withstand high-speed rotation without compromising its sealing efficiency, making it ideal for dynamic applications.

- Pressure Resistance: With its advanced material composition, the TB110 oil seal can handle higher pressures than many other standard seals.

Applications:

- Automotive: Common in high-performance vehicle components, including gearboxes, transmissions, and wheel hubs.

- Industrial Equipment: Used in rotary equipment, such as pumps, motors, and turbines, to prevent lubricant loss and contamination.

- Hydraulic Systems: Well-suited for hydraulic cylinders and actuators, ensuring reliable operation under pressure.

4. PPS Oil Seal: Specialized Material for Extreme Conditions

The PPS oil seal is made from polyphenylene sulfide (PPS), a high-performance material that offers excellent resistance to heat, chemicals, and extreme environments. It is particularly valuable in applications that involve high temperatures or aggressive fluids.

Key Features:

- Material Advantage: PPS is known for its high thermal stability, chemical resistance, and dimensional stability. This makes it ideal for environments where other materials might fail due to extreme heat or harsh chemicals.

- Low Friction: The low friction properties of PPS oil seals help reduce wear and tear on the sealing surfaces, increasing the seal’s life and improving overall system efficiency.

- Resistance to Aging: PPS oil seals maintain their sealing properties over extended periods of use, even in high-temperature and chemically aggressive environments.

Applications:

- Aerospace: Used in aerospace applications where seals must withstand extreme temperatures and pressures.

- Automotive: Used in engines and transmissions that operate at high temperatures.

- Chemical Processing: Suitable for sealing systems in chemical processing plants where resistance to aggressive fluids is necessary.

5. CFW BAFSL Oil Seal: Precision Sealing for Heavy Machinery

The CFW BAFSL oil seal is designed for use in heavy machinery and other demanding applications. It is often utilized in environments where high mechanical loads, dust, and moisture can compromise the integrity of conventional seals.

Key Features:

- Heavy-Duty Design: The CFW BAFSL oil seal is built to handle high mechanical loads, ensuring long-lasting performance even in challenging environments.

- Dust and Water Resistance: This seal is designed to withstand exposure to dust, dirt, and water, providing reliable sealing performance in industrial settings.

- Customized Solutions: The CFW BAFSL oil seal is often available in customized sizes and configurations, making it a flexible solution for a wide range of applications.

Applications:

- Construction Equipment: Used in bulldozers, excavators, and other heavy machinery to prevent fluid leaks and ensure proper operation.

- Mining Equipment: Ideal for use in mining operations where exposure to dirt, water, and extreme conditions is common.

- Agricultural Machinery: Often found in agricultural vehicles and equipment that require robust sealing solutions.

Conclusion: How to Select the Right Oil Seal for Your Application

Choosing the right oil seal for your application is crucial to prevent fluid leakage, enhance operational efficiency, and minimize maintenance costs. When selecting an oil seal, consider the following factors:

- Operating Conditions: Identify the temperature, pressure, and type of fluids the seal will be exposed to. For example, PPS oil seals are best for extreme environments, while TB110 oil seals are suited for high-speed, high-pressure applications.

- Material Compatibility: Different materials offer different benefits. Nitrile rubber (NBR) is excellent for oil and water resistance, while PPS offers superior chemical and heat resistance.

- Size and Fit: Ensure that the seal fits correctly with the shaft or housing to prevent leakage and maximize its lifespan.

Understanding the properties and applications of the M92074 oil seal, oil seal 12456, TB110 oil seals, PPS oil seal, and CFW BAFSL oil seal will help you make the best choice for your specific needs. If you’re uncertain about which seal to choose, it’s always a good idea to consult with a trusted manufacturer or supplier like Feiyun Seal Factory, who can provide customized sealing solutions and expert advice on selecting the right oil seal for your machinery and equipment.

Leave A Comment